Manufacture

Digital manufacturing of critical loading components for cable bridge

TK6926 NC Floor Type Boring Machine

Diameter of Boring Bar:φ260mm

Max. Loading Capacity on Worktable: 180T

Digital manufacturing of critical loading components for cable bridge

TJK6920-2 NC Floor Type Boring Machine

Diameter of Boring Bar:φ200mm

Max. Loading Capacity on Worktable:100T

Digital manufacturing of critical loading components for cable bridge

Vertical Lathe Machine

Maximum Turing Diameter:φ5000mm

Maximum Height of Worktable:3200mm

Digital manufacturing of critical loading components for cable bridge

Horizontal Lathe

Machining Length:18m

Digital manufacturing of critical loading components for cable bridge

FB260 NC Floor Type Boring Machine

Diameter of Boring Bar:φ260mm

Max. Loading Capacity on Worktable:600T

Digital manufacturing of critical loading components for cable bridge

TJK6920-1 Floor Type Boring Machine

Diameter of Boring Bar:φ200mm

Max. Loading Capacity on Worktable:40T

Digital manufacturing of critical loading components for cable bridge

SCHIESS Floor Type Boring Machine

Diameter and useful length:φ320mm*2500mm

Equipment Stoke:10000mm(X)*5500mm(Y)

Digital manufacturing of critical loading components for cable bridge

XK2850 CNC Plano-boring and Milling Machin

Working Table(Width*Length):6300mm*18000mm

Gantry Movement:18500mm

Digital manufacturing of critical loading components for cable bridge

Narrow-space automatic welding machine

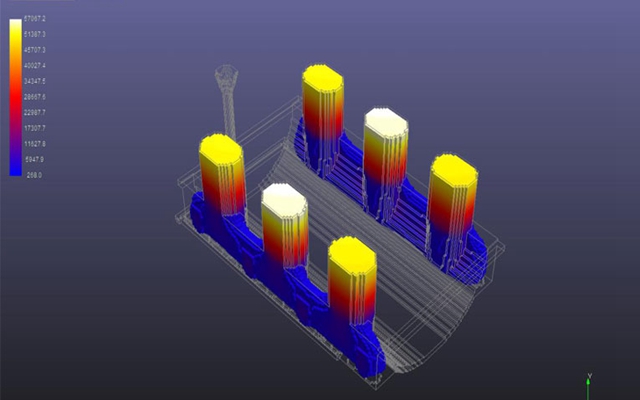

Advanced casting simulation manufacturing capability

The company possesses the professional casting base of cable clamp with an annual capacity of 4,000 tons, adopting digital simulation technology to simulate the solidification and filling process of steel castings for cable saddle and clamp so as to determine the optimal casting process scheme.

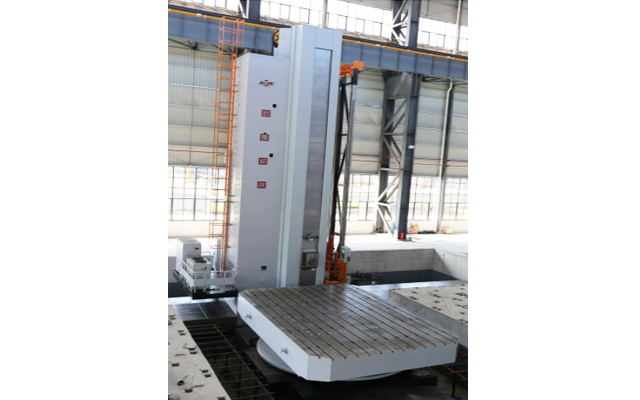

Manufacturing capacity for saddles

The company possesses the super equipment FB260 with the load of 600 tons for the overall machining of cable saddle.

The automatic welding capacity of vertical friction plate

Self-developed narrow spacing welding technology can achieve the automatic welding on narrow-space of 60mm and depth of 1000mm. Such technology has already been applied in the welding test of vertical friction plates for tower saddle at mid-pylon in the Ou River Beikou Bridge successfully.